Precision electronics assembly encompasses a array of meticulous techniques utilized in the manufacture of intricate electronic circuits. These techniques demand stringent control over component placement, soldering, and bonding to ensure optimal performance and reliability. A fundamental aspect of precision electronics assembly is the implementation of specialized tools and equipment designed to handle microscopic components with exceptional accuracy. Moreover, skilled technicians play a vital role in executing these sophisticated procedures, leveraging their expertise to achieve flawless assembly outcomes.

The precision required in electronics assembly is often determined by the pitch of the component pads on the circuit board, which can range from micrometers. Achieving precise placement and soldering at these small scales requires specialized equipment such as automated pick-and-place machines and high-resolution microscopes.

These sophisticated tools, coupled with the expertise of skilled technicians, enable the creation of highly complex electronic assemblies found in a broad range of applications, from telecommunications to aerospace and industrial systems.

The ongoing advancement in semiconductor technology continues to drive the need for even higher precision in electronics assembly. This movement necessitates the constant invention of new materials, techniques, and equipment to meet the increasingly demanding requirements of modern electronics.

Streamlining PCB Fabrication for High-Volume Production

In the realm of high-volume manufacturing, yield reigns supreme. When it comes to printed circuit board (PCB) fabrication, optimizing every stage is paramount to meeting expectations. Meticulous process control, from design optimization to the final assembly, ensures consistent quality and minimizes production downtime.

A key aspect of optimization lies in automation. Advanced machinery streamlines fabrication processes, reducing human error and increasing throughput. , Additionally, implementing real-time monitoring systems allows for immediate identification of potential issues, enabling swift adjustments. This proactive approach not only guarantees product quality but also reduces overall production costs.

By embracing these optimization strategies, manufacturers can achieve significant gains in PCB fabrication for high-volume production, ultimately delivering reliable products that meet the ever-evolving market demands.

Automated Solder Paste Inspection in SMT Manufacturing

In the rapidly evolving realm of Electronics Manufacturing, achieving precision and consistency is paramount. Automated solder paste inspection (SPI) has emerged as a crucial process within SMT manufacturing, ensuring the flawless application of solder paste onto circuit boards. Sophisticated SPI systems utilize cameras to meticulously analyze the deposited solder paste for critical parameters such as volume, placement accuracy, and surface coverage. These systems provide real-time feedback, enabling manufacturers to detect any defects or inconsistencies in the solder paste application process. By minimizing these issues, SPI significantly boosts the overall quality and reliability of SMT assemblies.

- Merits of Automated Solder Paste Inspection:

- Process Control

- Enhanced Efficiency

- Minimized Scrap Rates

Advanced Semiconductor Packaging Technologies accelerating Innovation

Semiconductor advancements are rapidly progressing, pushing the boundaries of performance and miniaturization. To keep pace with these demands, innovative packaging technologies have emerged as crucial enablers. These advanced techniques support the integration of multiple semiconductor dies into compact, high-performance packages, providing significant improvements in electrical and thermal performance. ,Therefore, they play a vital role in developing next-generation devices for applications such as artificial intelligence, data centers.

- Traditional packaging methods often face challenges in achieving the high density and bandwidth requirements of modern electronics.

- Advanced packaging technologies, such as 2.5D and 3D integration, overcome these hurdles by bridging multiple dies in a single package through innovative techniques like TSV (Through-Silicon Via) technology.

- ,Moreover, advancements in materials science and manufacturing processes have led to the development of high-k dielectrics and low-resistance interconnects, improving electrical performance and power efficiency.

The continued evolution of semiconductor packaging technologies will be essential for driving innovation in various industries. From high-performance computing, these advancements will enable the development of smaller, faster, and more efficient devices that shape the future of technology.

Challenges and Trends in Consumer Electronics Manufacturing

The consumer electronics production industry is a dynamic and ever-evolving landscape, constantly adapting to shifting demands. Manufacturers face a multitude of difficulties, ranging from the sourcing of raw materials to the implementation of cutting-edge technologies. Global supply chain vulnerabilities pose a significant threat, while increasing consumer expectations for innovation put pressure on companies to develop new and attractive products. However, these challenges are also accompanied by exciting trends that are reshaping the industry.

Environmental responsibility is a growing concern for consumers and manufacturers alike, leading to an focus on eco-friendly manufacturing processes and recyclable materials. Data analytics are being employed to optimize production lines, enhance product design, and personalize the consumer interaction. The rise of connected products is propelling demand for increasingly sophisticated electronics, necessitating continuous advancement in materials science and engineering.

Sustainable Practices in Electronics Recycling and Remanufacturing

Sustainable electronics recycling and remanufacturing initiatives play a crucial role in minimizing the environmental impact of the ever-growing electronic/digital/technological device industry. By implementing responsible practices, we can reduce electronic waste, conserve valuable resources, and alleviate pollution.

Various sustainable approaches are employed in this process, including:

* **Recycling:** Materials like metals, plastics, and glass are retrieved from old devices and utilized for manufacturing new products.

* **Remanufacturing:** Electronics are disassembled, inspected, and repaired to function as good as new. This process extends the usefulness of electronic devices.

* **Closed-Loop Systems:** Producers are increasingly adopting closed-loop systems where materials are recycled back into their own production processes, minimizing reliance on virgin resources.

These efforts not only benefit the environment but also contribute to a sustainable economy. By encouraging sustainable electronics recycling and remanufacturing, we can create a read more more responsible future for our planet.

Molly Ringwald Then & Now!

Molly Ringwald Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Barry Watson Then & Now!

Barry Watson Then & Now! Danny Pintauro Then & Now!

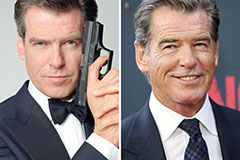

Danny Pintauro Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!